ReSpan​​​​​​​ – Recycling of chipboard materials

Subproject 2: Separation of multi-material systems and development of a recycling process for wood chipboards and wood fiber materials

Due to their mechanical properties and dimensional stability (low swelling and shrinkage behavior), particleboard and wood fiber materials are among the most important wood-based materials. Another advantage is the utilization of resources, since components such as sawmill residues, defective wood and waste wood that are not suitable for new solid wood products can also be utilized in their production. A disadvantage, however, is that in the case of wood shavings and wood fiber materials that are no longer needed or damaged, there is hardly any sensible subsequent use available so far, apart from thermal.

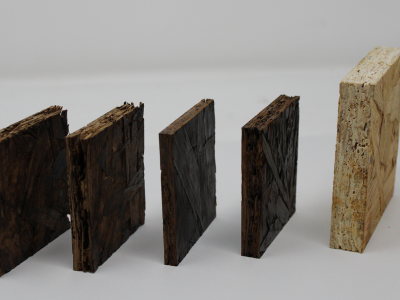

This is where the "Respan" research project comes in and aims to develop a recycling process for wood-based materials, in particular for MDF, OSB, flat pressed boards and pallet blocks. The aim is to recycle not just parts of the materials, but as many of them as possible.

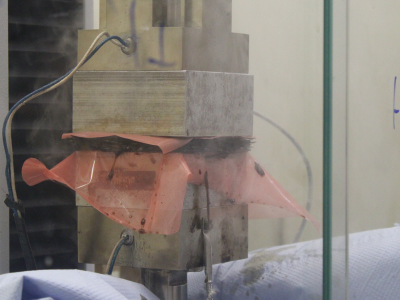

For this purpose, a recycling formulation chemically adapted to the respective board material must be found that is capable of dissolving the cured adhesive (including urea-formaldehyde (UF), phenol-formaldehyde (PF) or polymer diphenylmethane diisocyanate (PMDI)) in the materials without damaging the wood chips or fibers, so that the recycled pulp is again reactive to thermally induced crosslinking. This development step is the responsibility of the research division for Polymeric Materials and Composites (PYCO) of the Fraunhofer Institute for Applied Polymer Research (IAP).

In its sub-project, the HNEE will develop the necessary process technology that enables the separation of wood shavings and wood fiber materials from foreign substances such as coatings, lacquers, impurities and metallic foreign substances. In addition, the separation should result in wood shavings and wood fiber materials that are as pure as possible. The aim here is to enable the recycling process in practice on the pure materials. In addition, the HNEE is carrying out investigations into the geometry and properties of the chemically dissolved chips as well as mechanical tests and emission-relevant investigations on prototypes of the recycled board materials.

By implementing the recycling processes aimed in the project into the wood industry, the resource efficiency of the wood used could be further improved. This would make an important contribution to reducing the need for new wood and thus also to more sustainable forestry.

Research project partners

Fraunhofer Institute for Applied Polymer Research (IAP) (project coordination) - Research Division for Polymer Materials and Composites (PYCO)

Eberswalde University for Sustainable Development (HNEE) - Professorship Chemistry and Physics of Wood

Funding

The joint project "Recycling of chipboard materials" is commissioned and funded by the German Federal Ministry of Food and Agriculture (BMEL) through the Agency of Renewable Resources (Fachagentur Nachwachsende Rohstoffe e.V.) (FNR).

Funding code: 2220HV043B

Project duration: 01.06.2021 - 30.11.2023, extended until 31.12.2024

Head of project

Prof. Dr.-Ing. Alexander Pfriem (Alexander.Pfriem@hnee.de)

Contact persons

Ole Bäthmann B.Eng. (Ole.Baethmann@hnee.de)

Axel Mund B.Sc

Dipl.-Ing. (FH) Fabian Wulf